What is CNC lathe milling composite machining?

Car milling composite machining refers to the process of machining in

multiple directions using two different types of cutting tools, namely

turning tools and milling cutters, on the same CNC machine tool. Simply

put, a car milling composite machining center is equivalent to the

combination of a CNC lathe and a machining center.

Working principle of milling and turning composite machining center

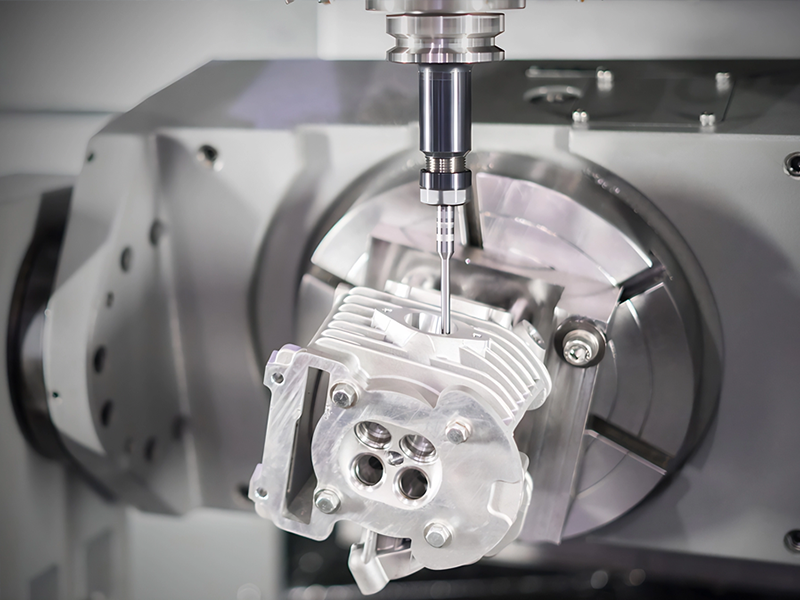

The CNC lathe milling composite machine can simultaneously achieve

turning and milling processing, combining the functions of traditional

lathes and milling machines. The following is an introduction to the

working principle of the lathe milling composite machine:

According to CAM software, perform numerical control programming and

generate numerical control programs that can be recognized by the CNC

machine tool. Upload the milling part program, and the machine tool will

perform the initial turning steps normally. The cutting rotating tool

will remove excess material and process the desired shape.

-After the turning process is completed, the turning and milling

composite machine will rotate the tool to proceed to the next milling

process, completing the machining of the side holes and irregular

surfaces of the parts.

Compared with the parts processed by CNC lathe milling composite

machine tools, the precision is higher, the accuracy is higher, and the

efficiency is higher. At the same time, this process is suitable for

processing various materials and complex parts.

Characteristics of turning milling composite machining center

Numerical control turning and milling composite machining is mainly

achieved through milling processes such as flat milling, drilling and

tapping, and groove milling on lathes. The following are the

characteristics of turning and milling composite machining centers:

1. The car milling composite machining center uses high-precision built-in spindle

2. Free moving operation panel improves work efficiency

3. The model mainly produces various small and complex parts in large

quantities, with high-speed processing and diversified processing

4. Especially for slender and complex processes, they can be

processed and formed in one go, and automatic feeding devices can be

configured to improve efficiency;

5. Widely applicable materials include titanium, copper, iron, aluminum alloy, stainless steel, Teflon, and other materials.

The advantages of combined milling and turning processing

With the rise of intelligence and high-end fields, the demand for CNC

turning and milling parts in the industry is increasing day by day. The

combination of turning and milling technology will solve many problems

for emerging industries. Let's take a look at the advantages of

combination of turning and milling:

1. Faster production efficiency: The turning milling composite

completes most of the processes in one clamping, quickly and efficiently

completing the product.

2. Higher accuracy: Reducing the number of clamping times can better

ensure accuracy, and the machine equipment has online detection

function, which can achieve in-situ detection and accuracy control of

key data in the manufacturing process.

3. Lower production costs; The shortening of the manufacturing

process chain and the reduction of equipment required for products, as

well as the reduction of the number of fixtures, workshop space, and

equipment maintenance costs, can effectively reduce the overall

investment, production operation, and management costs of fixed assets

4. Higher flexibility and adaptability: The turning and milling

composite machine tool can adapt to multiple varieties and small batch

production methods, with multiple processing functions and high

flexibility. In production, different cutting tools and processing

strategies can be selected according to different part requirements to

achieve rapid production changes and adjustments.

5. More energy-efficient and environmentally friendly: The turning

and milling composite machine tool adopts advanced energy-saving

technology and environmentally friendly materials, which can reduce

energy consumption and environmental pollution.

Main application areas of CNC lathe milling composite machining

-Aircraft aviation parts manufacturing, milling and turning composite

are widely used in the processing of complex rotating parts, such as

aircraft engines, fuel accessories, compressor blades, etc

-Mold processing: The combination of turning and milling can achieve

complex shape processing of parts, meeting the high-precision

requirements of mold manufacturing

-Automotive parts: automobile engine crankshaft, automobile transmission parts

-Medical device manufacturing: used for manufacturing artificial joints, dental equipment, surgical instruments, etc

- Electronic equipment manufacturing: used to manufacture electronic

components, semiconductor devices, microelectronic components, etc.

ensuring their accuracy and performance.

At Jingtianxia, we can obtain high-quality turning and milling composite machining services

At Jingtianxia, we have advanced equipment and a professional technical

team to manufacture high-precision turning and milling parts for you.

You only need to upload CAD files to receive DFM analysis, and we will

serve your project at the most advantageous price and fastest delivery

time.

Conclusion

As a core technology in modern manufacturing, turning milling

composite technology is gradually changing traditional production

methods and bringing us more efficient and precise production

capabilities.

In the future, with the continuous development and improvement of

this technology, it will demonstrate greater potential and value in more

fields.