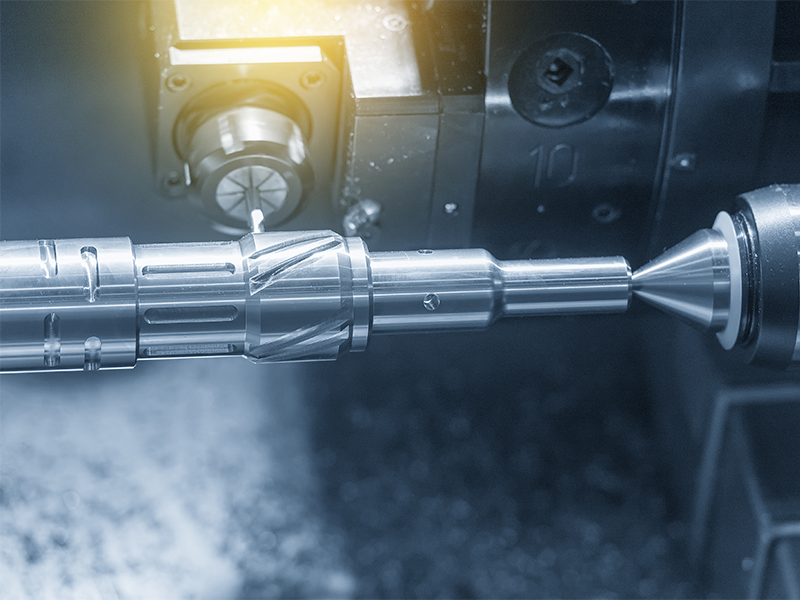

The five axis CNC machining center achieves cutting of the tool at any angle in space through the linkage control of the X, Y, Z axes and two rotating axes. This technological breakthrough has increased the efficiency of complex surface machining by more than three times, especially suitable for the manufacturing of parts with spatial curvature such as impellers and aircraft engine blades, and has become a core equipment in the field of precision machining.

Core Technology Breakthrough and Application Value

The traditional three-axis equipment requires multiple clamping to complete multi-faceted machining, while the five axis system can achieve it through one positioning, reducing cumulative errors and avoiding surface damage caused by repeated clamping. In mold manufacturing, a five axis machining center can complete corner cleaning of deep cavity structures; In the field of artistic carving, it is possible to replicate three-dimensional textures that are difficult to achieve with traditional handicrafts. The combination of it and CNC turning technology can further complete turning and milling composite machining, expanding the possibilities of the process.

Industry impact and development trends

Five axis technology is rapidly penetrating from aerospace to civilian fields. Medical device companies utilize their complex bone trabecular structures for processing biomimetic joints, while energy equipment companies use them to manufacture precision flow channels for turbines. In the future, with the integration of intelligent sensing technology, five axis equipment will achieve real-time adaptive adjustment of cutting force, further improving machining stability.

The cornerstone equipment of high-end manufacturing

The five axis CNC machining center transforms design drawings into precise physical entities through multidimensional motion control and intelligent programming, which is a key technology to break through the bottleneck of complex part manufacturing.

frequently asked questions

Q: Is the five axis equipment suitable for small-scale production?

A: Although skilled in processing complex parts, it can also adapt to flexible production needs through fast tool changing systems and modular fixtures.

Q: What technical reserves are required to operate a five axis machine tool?

A: Specialized skills such as multi axis programming, tool path optimization, and collision detection are required, with high demands on the comprehensive quality of operators.